Description

FUELSTAT® On-site Test Kits - Diesel

The On-site FUELSTAT® Diesel test kit box includes 8 individual tests.

Why FUELSTAT® DIESEL?

FUELSTAT® DIESEL is your IATA-approved, on-site diesel fuel test, delivering quick and precise contamination detection. Here's why you should use it:

-

Rapid Detection: Detect both high and low contamination levels within 10 minutes.

-

Accurate ID: Identify specific contaminants in your fuel.

-

Early Warning: Detect contamination before it escalates.

-

Informed Action: Easily plan your response.

-

Simple Record-Keeping: Keep track with user-friendly test paddles.

-

Disposable Components: Everything is disposable for your convenience.

Background:

Different microorganisms, like the diesel bug (Hormoconis resinae), thrive in diesel fuel. They can cause filter blockages, component failures, and tank corrosion. This test quickly screens for contaminants, offering results in 10 minutes instead of 72 hours like traditional tests.

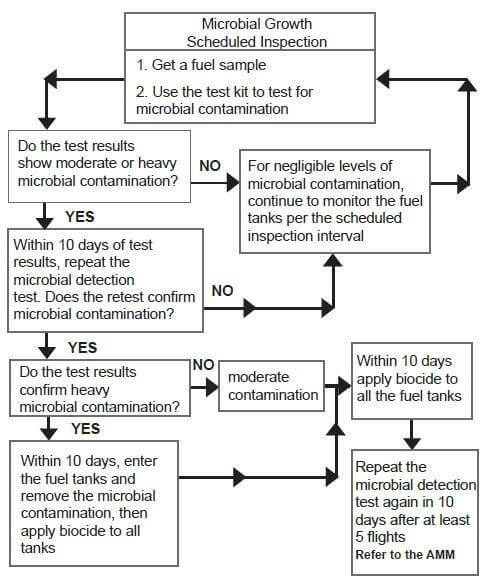

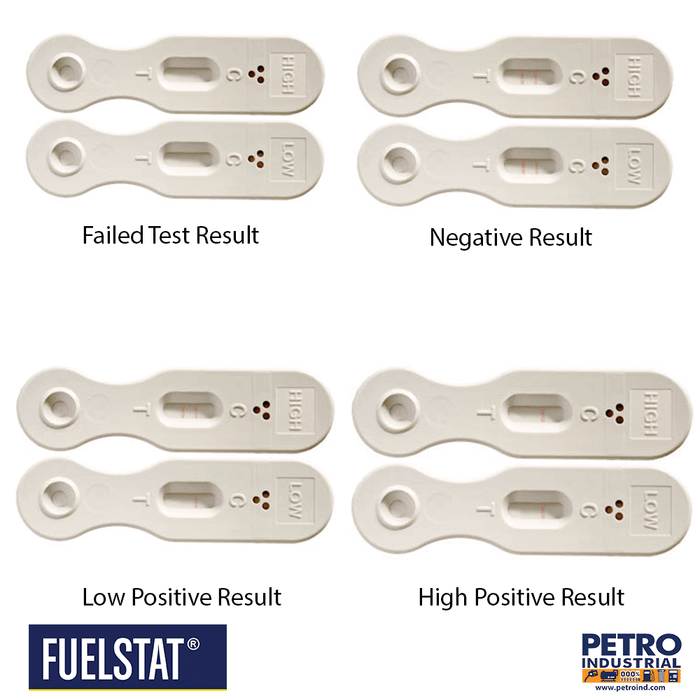

FUELSTAT® resinae PLUS DIESEL uses a precise traffic light scale:

- Negligible (Green) – Minimal contamination

- Low Positive (Amber) – Moderate contamination

- High Positive (Red) – Significant contamination

Every Test Kit includes six devices. Choose FUELSTAT® DIESEL for swift, accurate fuel contamination detection.

Test Kit Contents

- Each heat sealed foil pouch contains a Paddle with desiccant sachet and pipette in one section and Sample Extraction Bottle with flat cap, dropper cap and instructions for use in the other section.

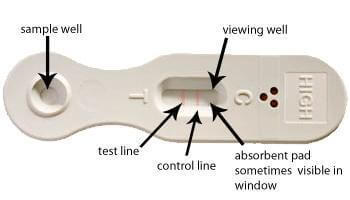

- Paddle: Plastic base with 6 lateral flow devices affixed.

- Preparation Bottles: 175ml plastic bottle with flat cap and “dropper” cap containing 3.0ml of Sample Extraction Liquid.

- Disposable, single use, plastic pipette.

- Instruction leaflet.

What is the Diesel Bug?

The Diesel Bug is a group of organisms that inhabit the fuel-water interface, residing in the water while consuming the fuel. Among these, H res is the most damaging, responsible for filter blockages and tank corrosion when left unattended. This consortium also comprises bacteria and other fungi, including yeasts, which can cause fuel system issues.

How FUELSTAT® Works

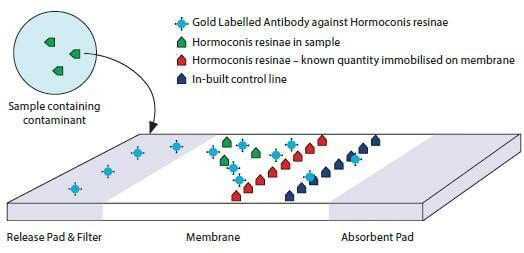

- The FUELSTAT® resinae PLUS DIESEL test utilises lateral flow technology and antibodies to H Res, bacteria and fungi which grow in diesel fuel.

- The gold-labelled antibody is immobilised in the Release Pad under the sample well.

- The sample containing an unknown amount of contamination is added to the sample well and this re-hydrates, allowing the reagents to flow up (wicking) the membrane towards the absorbent pad.

- Any large particles in the sample, which may block the reaction, are blocked by the filtering action of the pad.

- During the wicking, the contamination in the sample will bind to the specific antibodies.

- As the liquid reaches the Test Line (T) any free gold-labelled antibodies will bind to the test line.

- This means if more contamination is in the sample than the threshold engineered, there will be no antibodies to bind to the Test Line, no red line will appear, and this is a POSITIVE result.

- If the amount of contamination in the sample is lower than the threshold, there will be free antibodies to bind to the Test Line, a red line will appear, and this is a NEGLIGIBLE result.

- The quantities of materials immobilised in the device are engineered to provide results at the different thresholds of H Res, bacteria and fungi in each of the test devices on the Test Paddle.

Sample Preparation

- Take a sample from the fuel tank into a clean container.

- Allow the sample to “settle” and any water to accumulate at the bottom of the sampling container.

- Ideally, the sample should be drawn from the tank sump or lowest point from a water drain point.

- Alternatively, draw a tank bottom sample using a dipped sample tube from the tank fill aperture.

- For vehicle tank testing, if it is impossible to harvest a tank bottom sample then the contents of the primary fuel filter is the next best place.

- This sample however may not represent the tank bottom.

- Any sample taken should be tested as soon as possible after collecting and, in any event within 6 hours to maintain the integrity of the sample.

NOTE : When possible, test the water phase of the sample taken from the fuel tank. Testing the water phase will provide more accurate results than testing the fuel phase.

Contact PETRO industrial's team of bulk fuel storage and dispensing specialists for more information today!