Custom Solar-Powered Emergency Safety Showers for the Mining Industry

PETRO designed and built custom solar-powered emergency showers and eyewash stations for a mining client — delivering compliance, safety, and off-grid reliability.

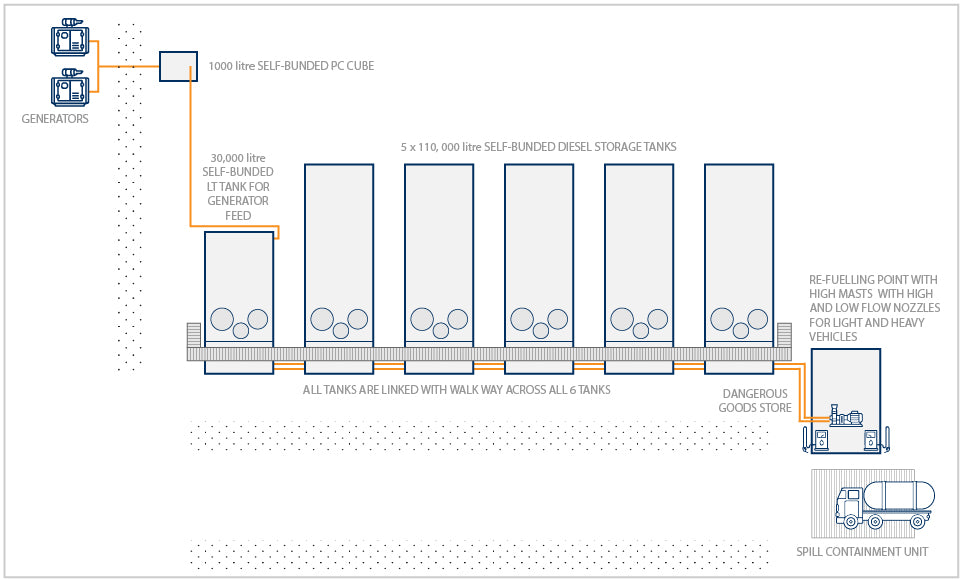

Our client, a prominent player in the mining industry, required a robust and efficient fuel supply system to sustain Light and Heavy Vehicle refuelling along with some generators operating on-site. PETRO Industrial was entrusted with the task of designing and implementing a comprehensive solution tailored to meet their specific needs.

We designed this innovative bulk fuel farm, featuring 5 PETRO LT Series 68,000L Bulk fuel tanks seamlessly interconnected with linking kits. Each tank was equipped with TRAP breather assemblies to efficiently regulate moisture and prevent dust ingress, safeguarding the integrity of the stored diesel. The Fuel Farm was strategically designed to facilitate Light and Heavy Vehicle Refueling.

Complementing the fuel storage setup, a 6m Dangerous Goods store was engineered to serve as the central control module for the Fuel Farm as well as house the unloading pump.

This DG Store not only ensures compliance with safety regulations but also houses two high masts equipped with Low and High flow, dual hose nozzles and one High flow nozzle, contributing to a comprehensive and secure fuel distribution system.

Additional to the Fuel Farm tanks, a fully customised PETRO LT Series 30,000L Bulk fuel tank was installed to feed a PC Cube 1,100L daytank that supplies 2 generators on site. All necessary transfer systems were installed in the full height, lockable pumpbay.

All refuelling points were equipped with fire extinguishers, safety eye wash and shower stations. PETRO Industrial completed the setup with Spill Containment Units and the refuelling points and near the 6m Dangerous Goods store. Environmentally complying to all standards.

Safe Storage:

All pumping equipment found its home in a dedicated 6m Dangerous Goods Store. This secure facility housed NMI approved meters, an iPETRO Pro fluids management system, tank gauging, and five duty standby transfer pumps, guaranteeing compliance with industry standards and safety regulations.

Efficient Monitoring:

Our integrated solution included a sophisticated tank gauging system, providing real-time visibility into fuel levels. This ensures the client can proactively manage fuel supply, minimizing downtime and optimizing operational efficiency.

Enhanced Containment Measures:

To bolster safety during road tanker unloading and light vehicle refueling, our solution incorporated spill containment units. These units provide an added layer of protection, mitigating the risk of spills and ensuring compliance with stringent environmental regulations.

Accessibility and Safety Features:

The fuel tanks were strategically fitted with easy-access walkways, facilitating regular checks and maintenance. Moreover, emergency spill kits, eye wash stations, safety showers and fire extinguishers were positioned for quick response to unforeseen situations, prioritizing safety and environmental protection.

OUTCOME:

The implementation of our comprehensive fuel farm has significantly elevated our client's operational capabilities. With a seamless and secure fuel supply infrastructure, they can now power their generators efficiently and keep their vehicle fleet fuelled up, ensuring uninterrupted operation.

The attention to safety features, compliance, and accessibility underscores PETRO Industrial's commitment to delivering tailor-made solutions that not only meet but exceed our clients' expectations. This case exemplifies our expertise in providing holistic solutions for complex fuel storage and supply requirements in demanding industrial settings.

In closing, this case study highlights our successful collaboration and impactful solutions. For more information or to discuss how we can tailor our expertise to your unique needs, contact our team.

We're eager to contribute to your success. Reach out today at sales@petroindustrial.com.au | 1300 987 789.

PETRO designed and built custom solar-powered emergency showers and eyewash stations for a mining client — delivering compliance, safety, and off-grid reliability.

Discover how PETRO designed a custom mobile 4,500L solar-powered fuel storage and dispensing solution for a mining client — complete with smart tracking and cloud-based reporting.

The iPETRO Link Gateway is the ultimate bridge between your fuel storage and dispensing systems and the powerful iPETRO VMI Cloud dashboard. Engineered for seamless integration and total visibility, this device consolidates data from any Fluid Management or Automatic Tank Gauging (ATG) system—no matter how remote or distributed your sites are.